Crescent Textile Solutions is a manufacturer of custom textile solutions, including wool and synthetic yarns, roving, batting, and fabric. Crescent has been in business for over 100 years, and is certified to be NAFTA and Berry Amendment compliant.

We are a family-owned business with third generation family members operating the business in the northern Wisconsin community of Two Rivers. For over six generations, the descendants of Matthew Webster have worked in or owned textile enterprises. This rich history is part of our corporate culture and we pride ourselves in having long-term relationships with our customers.

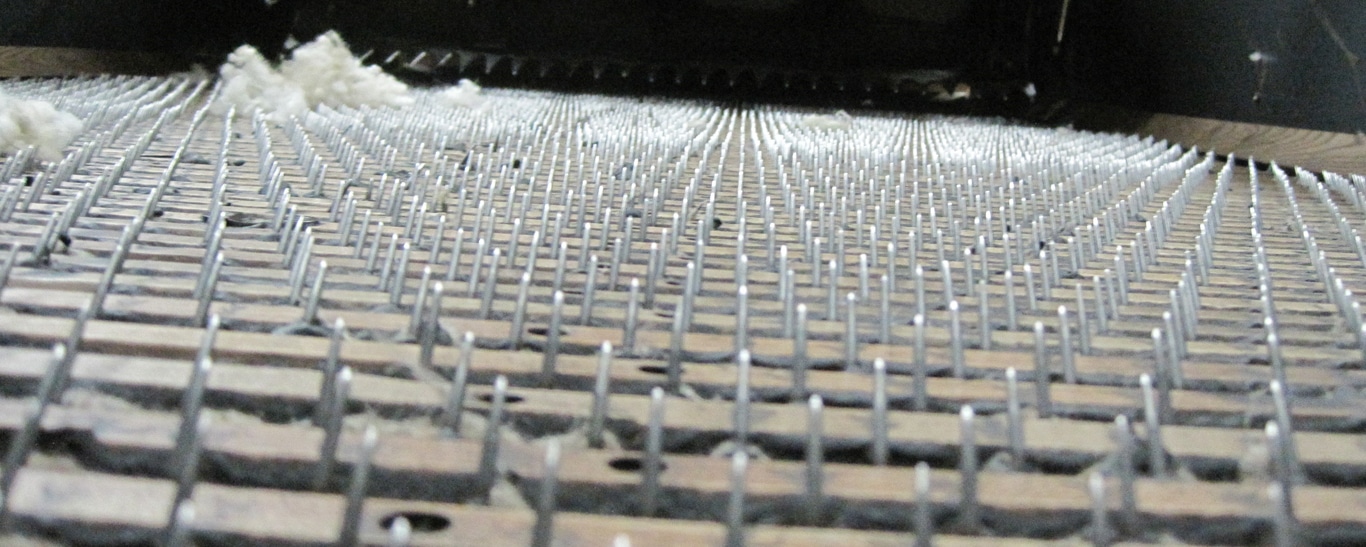

We operate on a ring spinning system, and our typical fiber length averages between 1.5 inches – 4 inches.

The following is a partial list of fibers we convert to yarns:

Natural Fibers

Synthetic

Crescent Textile Solutions History

In 1855, at the age of 27, Matthew Webster and three of his brothers emigrated to the United States of America from Pudsey, England. While in England, Matthew had worked from a very young age in a textile mill alongside his father, Jonathan Webster. After Jonathan’s death in 1850, the family travelled by ship across the Atlantic, sailed up the Hudson River to Albany, New York and then by Erie Canal to Wayne County, Ohio.

In 1867, Matthew and his brothers started construction of a woolen mill at Pine Creek, an area adjacent to Rushford, Minnesota. Known as the Toledo Woolen Mill at Pine Creek, the firm made blankets, flannels, cloth and hand-knitting yarns. In 1875, Matthew Webster bought out his brothers and with the help of his sons Daniel and William Walter, operated the mill until his death in 1893 at the age of 65.

In 1904, William Walter Webster purchased a woolen mill from his uncle in Rushford, MN and eventually built a state-of-the-art woolen mill in Winona, Minnesota which he sold to a group of businessmen in 1923. That same year, William Walter’s sons, Archibald and Theodore, moved to Two Rivers, Wisconsin to take ownership of an existing knitting mill there. They renamed the business Crescent Woolen Mills, and since that time, three generations of the Webster family have been involved in the operation of the business.

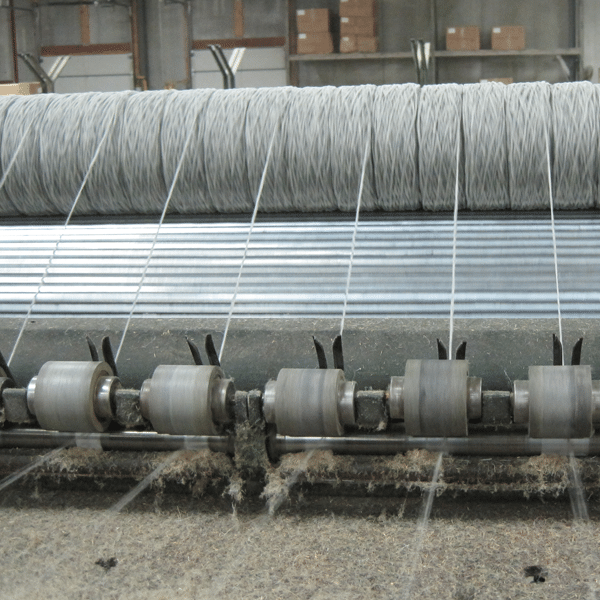

In late 2013, Crescent Woolen Mills expanded its offerings with the purchase of Owen Glove Lining, a manufacturer of knitted wool, wool-blend and SEF lining fabrics. Owen Glove Lining equipment and operations were moved to the Two Rivers location, which allowed Crescent Woolen Mills to control the quality of the end product by spinning the yarn, then blending and knitting the linings to customer specifications.

Both companies were purchased by Miller Waste Mills, a textile recycling company in Winona, Minnesota in 2017. Since that time, the Webster family has continued their legacy in operations and manufacturing, while building improvements and the addition of advanced equipment have expanded the company’s traditional yarns and glove lining fabric product lines to include new blends, pencil roving, and batting, as well as fabric suitable for a wide range of applications. In 2025, the companies joined forces to become Crescent Textile Solutions, a thriving, family-run operation that is founded on a strong sense of customer service and craftsmanship with special focus on setting the standard for high-performance textile solutions.