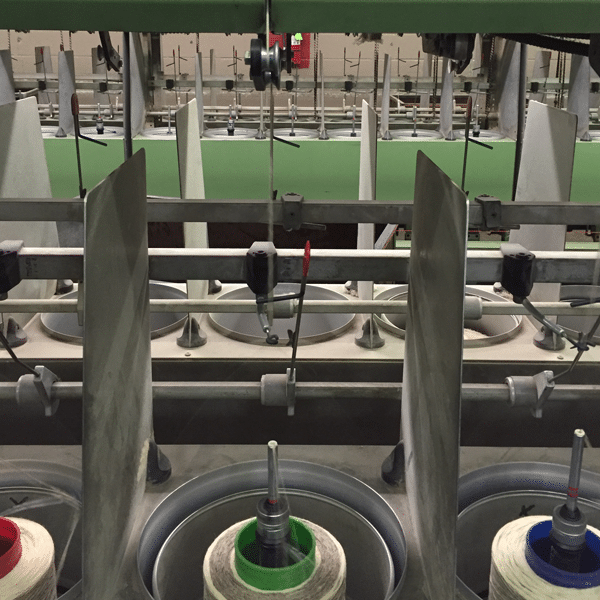

The final stage in yarn formation is twisting, where plied yarns receive a secondary twist for added durability, elasticity, and structure. The twist level, expressed in twists per inch (TPI), is computer-regulated for precision. This ensures uniform tension and strength, making the resulting twisted yarn ideal for high-strength textile applications.