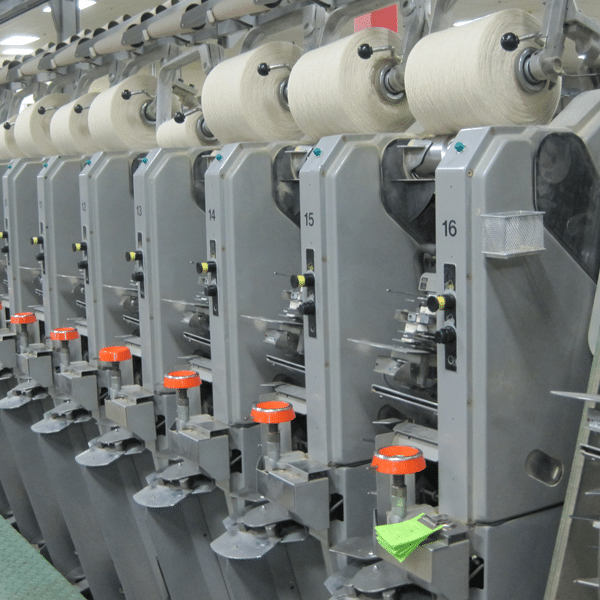

The winding process involves transferring yarn from bobbins to cardboard cones to ensure uniform consistency and efficiency. Our computer-controlled winding system removes imperfections, utilizing air-splicing technology to eliminate knots and make our industrial-strength yarns ready for knitting, weaving, or further processing.